Modular Build

At Trigon Projects, our modular construction capability is underpinned by our dedicated 7,000sqm hardstand, purpose-built to support multiple modular projects simultaneously. Whether delivering remote accommodation, healthcare facilities or education spaces, our off-site construction approach ensures faster programmes, greater quality control, and safer delivery, all while minimising disruption to live sites.

Our Approach.

-

Modular Construction

Our modular units are built offsite in a controlled construction yard, allowing for high-quality fabrication with minimal weather delays. This streamlined approach ensures greater efficiency and precision before the modules arrive onsite.

-

Site Works

While the modules are being constructed offsite, we carry out essential site preparation, including earthworks, footings, civil works, and service connections. This parallel workflow reduces overall project timelines and ensures a smooth installation process.

-

Transport

Once completed, the prefabricated modules are securely transported to site using specialised transport methods. Detailed logistics planning ensures safe delivery, factoring in route restrictions, permits, and site access constraints.

-

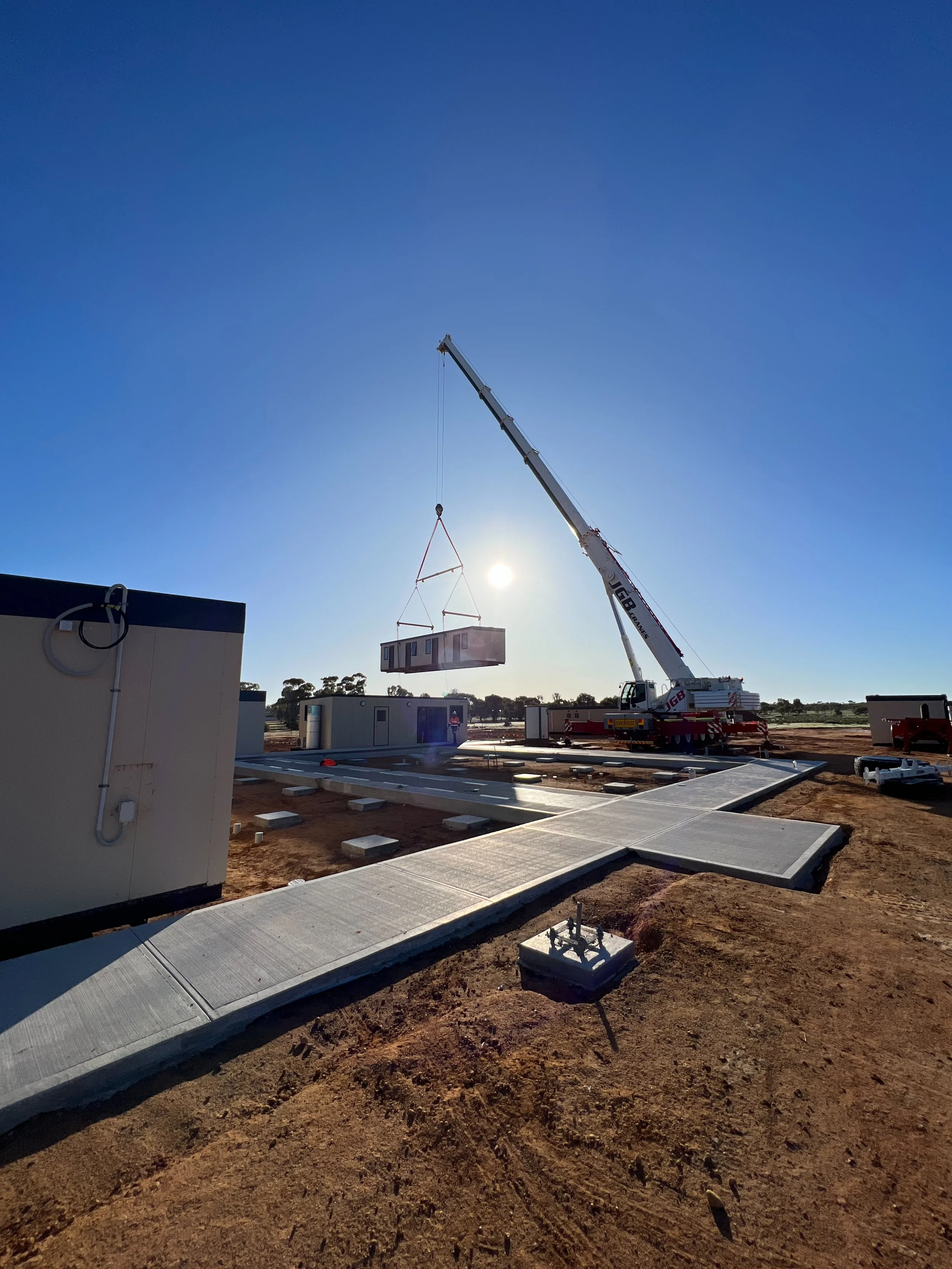

Delivery

On arrival, the modules are craned into position. They are secured to prepared footings, connected to services, and completed with minimal disruption — offering a faster, more efficient build with consistent quality.

-

Commissioning & Handover

Rigorous testing, commissioning, and quality assurance processes are completed to meet medical-grade standards. We provide LARU-compliant documentation, staff training, and post-handover support to ensure a smooth transition into full operation.

CBH Moora Project >

Trigon Projects takes a methodical, service-first approach to modular construction, ensuring site infrastructure is fully prepared before module placement. We begin with detailed site investigations and surveys, adapting to unforeseen conditions with engineered solutions such as soil conditioning and improved drainage capacity. By completing all concrete pours upfront, we streamline trade sequencing, reduce curing time, and accelerate programme delivery. Our integration of civils, electrical, and hydraulic works allows for seamless service connections, while strategic planning ensures operational continuity, such as implementing temporary power solutions while awaiting permanent connections. Once in place, prefabricated buildings are craned in, upgraded to meet Australian Standards, and fitted with essential services. This approach minimises site disruption, enhances efficiency, and delivers high-quality modular solutions.